Jan 16, 2026

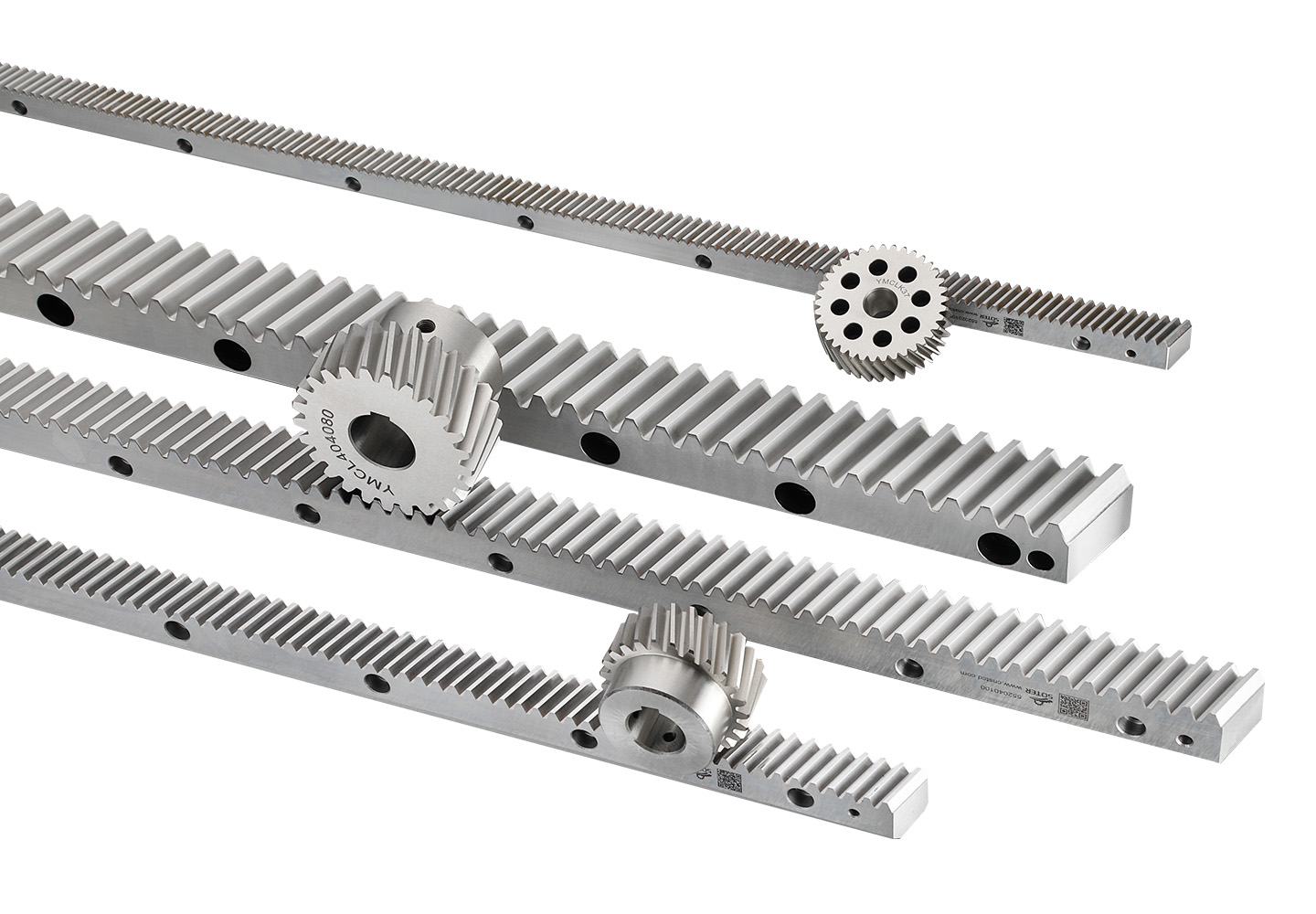

A Straight Gear Rack Factory often emphasizes the efficiency advantages of straight gear racks in mechanical systems. Straight gear racks, also known as spur gear racks, consist of linear teeth that engage directly with a matching pinion. Unlike helical gear racks, which have angled teeth, straight gear racks provide straightforward tooth contact that reduces sliding motion. This design feature plays a critical role in improving transmission efficiency while reducing power losses in various industrial applications, including CNC machinery, automation systems, and conveyor equipment.

The primary reason straight gear racks enhance transmission efficiency is their direct tooth engagement. When the pinion meshes with the rack, the teeth contact each other almost instantaneously along the line of action. This reduces sliding friction between teeth, which is a major source of energy loss in angled or helical gear systems. As a result, more of the input energy is effectively transferred to linear motion, improving overall mechanical efficiency and reducing the need for additional power.

Straight gear racks provide consistent and predictable load distribution across each tooth. Because the teeth are perpendicular to the rack axis, each tooth fully engages with the pinion in a simple linear motion. This uniform contact reduces uneven stresses and reduces energy dissipation caused by micro-slipping or partial contact. Systems that use straight gear racks can therefore operate smoothly, maintain higher efficiency under variable loads, and experience less mechanical wear over time.

The straightforward engagement of a straight gear rack simplifies system design and maintenance, indirectly contributing to efficiency. Unlike helical gear racks, which require precise alignment to prevent axial thrust and uneven wear, straight gear racks are easier to install and align. Lower alignment errors reduce energy losses caused by misaligned teeth or unnecessary friction, ensuring the system operates closer to its theoretical efficiency. Additionally, maintenance intervals are easier to schedule and manage, preventing efficiency drops due to wear or misalignment over time.

Straight gear racks are particularly advantageous in high-speed applications. Because there is sliding between teeth, heat generation is reduced, and lubrication requirements are simplified. This enables the system to sustain high operational speeds without significant efficiency losses. The linear, predictable engagement of teeth allows for precise control of movement and torque transmission, which is essential in robotics, automation, and other high-speed industrial applications.

Choosing a straight gear rack is ideal for applications where high transmission efficiency and predictable performance are required. They are commonly used in CNC machines, material handling systems, linear actuators, and automotive steering mechanisms. While straight gear racks offer efficiency advantages, they are less suitable for applications requiring extremely quiet operation or heavy load distribution over multiple teeth, where helical racks might be preferred. A Straight Gear Rack Factory typically recommends application-specific designs to balance efficiency, load capacity, and durability.

The use of a straight gear rack can significantly improve transmission efficiency due to its direct tooth engagement, minimal sliding, and predictable load distribution. Its straightforward design simplifies alignment and maintenance, further contributing to efficient power transfer. By understanding the relationship between tooth engagement and mechanical efficiency, engineers and manufacturers can optimize systems for performance and reliability. A Straight Gear Rack Factory combines material selection, precise machining, and alignment optimization to produce high-quality racks that deliver consistent and efficient operation in industrial applications.