Jan 09, 2026

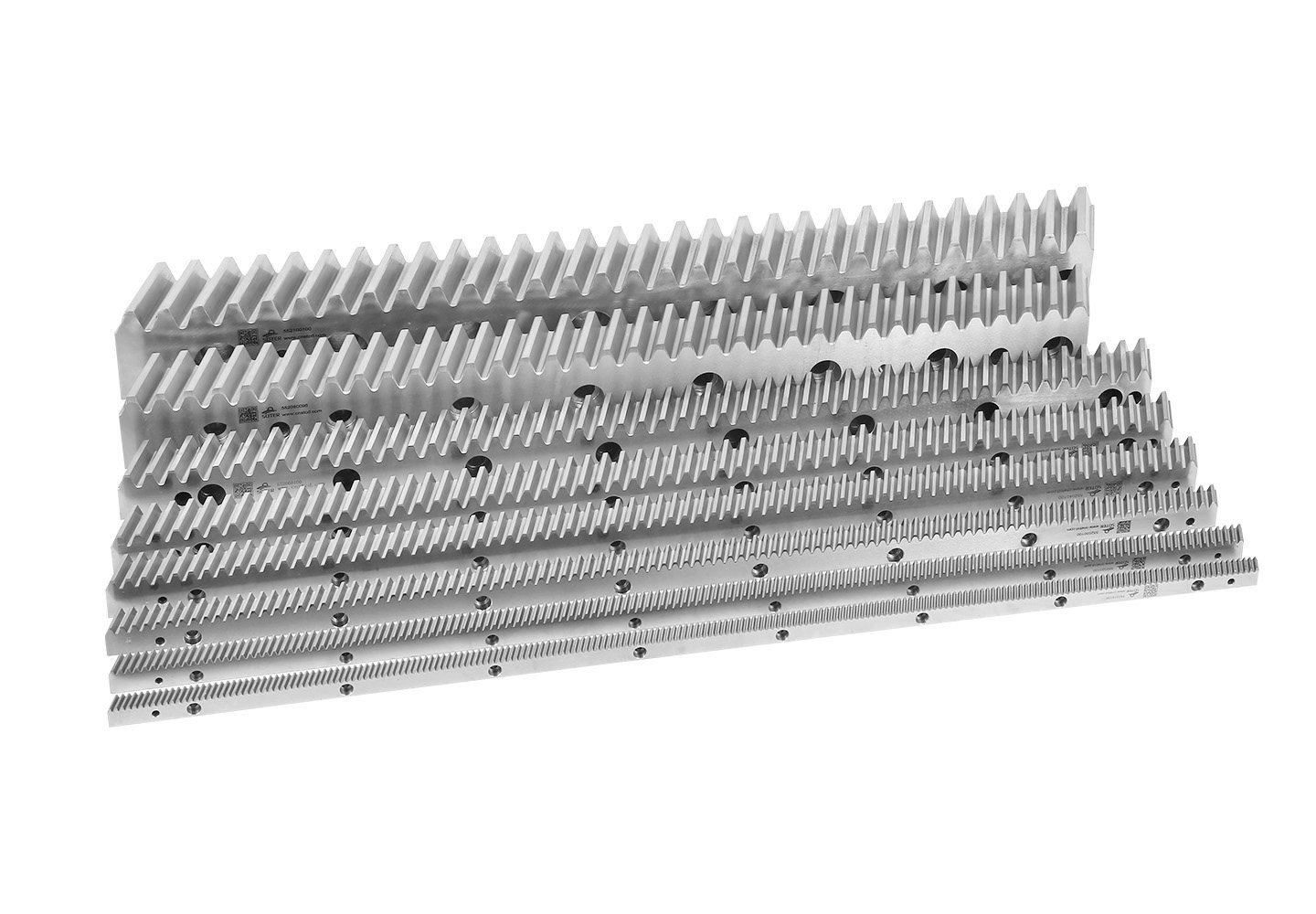

A Helical Gear Rack Factory carefully considers the helix angle as one of the critical parameters in gear design. The helix angle, defined as the angle between the tooth line and the gear axis, directly influences the performance characteristics of the gear rack, including load distribution, noise levels, efficiency, and durability.

The helix angle significantly affects how forces are transmitted along the gear teeth. A larger helix angle allows for a more gradual engagement between the pinion and the rack, which distributes load over multiple teeth simultaneously. This results in smoother motion and reduces localized stress on individual teeth. Consequently, gear racks with optimized helix angles are less prone to wear and tooth failure, extending service life and maintaining consistent operational performance.

One of the notable benefits of the helix angle is its effect on noise and vibration. A gear rack with a well-chosen helix angle produces quieter operation compared to a straight-tooth design. The gradual engagement reduces impact forces as the teeth mesh, lowering vibration and operational noise. This is particularly important in applications such as robotics or precision machinery, where quiet and smooth operation is critical for both performance and user satisfaction.

Helix angle also influences the efficiency and speed potential of a gear rack system. Gear racks with moderate helix angles can operate at higher speeds without generating excessive heat or vibration. The sliding contact inherent in helical teeth generates more friction than straight teeth, which slightly reduces efficiency, but careful selection of the helix angle balances load distribution and sliding friction to maintain suitable performance. Factories often run simulations and tests to determine the helix angle that provides the combination of speed, efficiency, and durability for each application.

The contact pattern of teeth in helical gear racks affects lubrication requirements and wear patterns. A larger helix angle increases the sliding motion along the tooth face, which may cause higher wear if lubrication is inadequate. Selecting the correct lubricant and maintaining proper lubrication intervals becomes essential to preserve the performance benefits offered by the helix angle. Properly maintained systems exhibit reduced surface fatigue and extended component life.

Different applications demand different helix angles. For instance, heavy-load industrial conveyors may require smaller helix angles to reduce sliding friction while maintaining strength, whereas precision automation equipment may benefit from larger angles to enhance smooth motion and reduce vibration. A Helical Gear Rack Factory typically customizes the helix angle based on application requirements, material properties, and operational conditions to achieve the desired balance of strength, efficiency, and quiet operation.

The helix angle of a helical gear rack is a fundamental design feature that influences load distribution, noise reduction, efficiency, and wear characteristics. By carefully selecting and optimizing the helix angle, manufacturers ensure that the gear rack performs reliably under specific operating conditions. A Helical Gear Rack Factory combines material selection, precise machining, and angle optimization to produce high-performance gear racks capable of meeting the demands of modern industrial applications. Understanding these relationships allows engineers and users to choose gear racks that deliver good performance, durability, and efficiency.