Oct 24, 2025

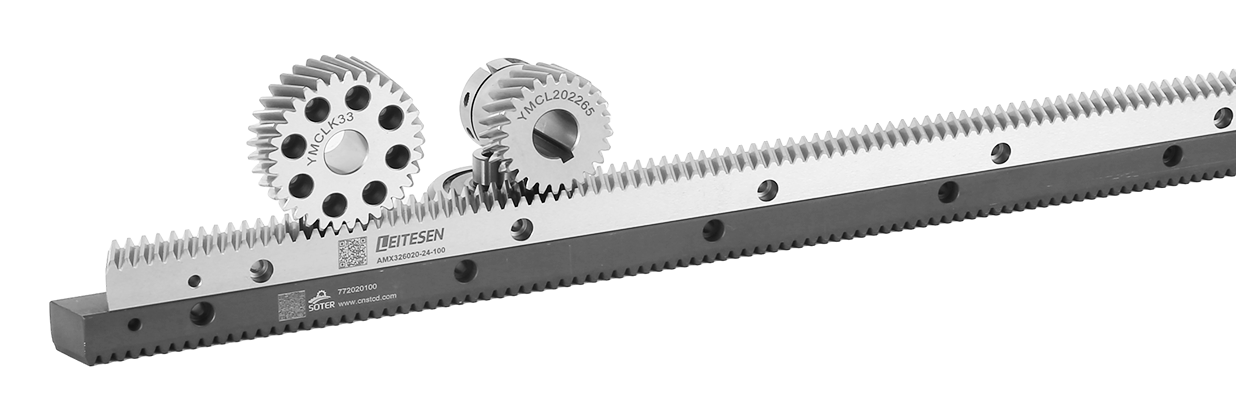

In modern mechanical systems, the ability of linear motion components to withstand high loads is crucial for both safety and performance. Applications such as CNC machines, automated assembly lines, and heavy-duty robotic arms rely on gear racks to transmit motion reliably under significant forces. The load-bearing capacity of a Precision Gear Rack directly influences the system’s operational stability, efficiency, and longevity. Understanding how gear racks perform under high stress is, therefore, essential for engineers and operators.

Several factors determine the load a gear rack can safely handle:

Failure to optimize any of these factors can compromise load capacity and cause mechanical failure.

A Precision Gear Rack subjected to heavy loads must resist both static and dynamic stresses. Key considerations include:

By designing for adequate safety margins and material toughness, these risks can be mitigated, ensuring consistent performance.

To high-load capacity, several engineering strategies are applied:

These design measures allow Precision Gear Racks to perform reliably even under demanding operational conditions.

Even a high-quality gear rack requires proper maintenance to sustain load-bearing capacity:

Consistent maintenance extends service life and preserves mechanical performance.

Precision Gear Racks with high load capacity are widely used in industrial automation, heavy-duty machining, and material handling systems. In these contexts, they must reliably transmit motion and maintain positional accuracy under forces ranging from several hundred kilograms to multiple tons. Properly designed and maintained racks demonstrate long service life even in continuous operation, highlighting the importance of material quality, tooth design, and installation.

The load-bearing capacity of a Precision Gear Rack is critical to the performance and reliability of mechanical systems operating under high stress. Material selection, tooth design, surface treatment, and proper installation all play key roles in determining how much load the rack can sustain. Additionally, regular maintenance and correct operational practices ensure that the rack continues to perform accurately over time. When engineered and maintained correctly, high-quality gear racks can withstand significant forces, providing reliable linear motion in even the demanding industrial applications.