Oct 27, 2025

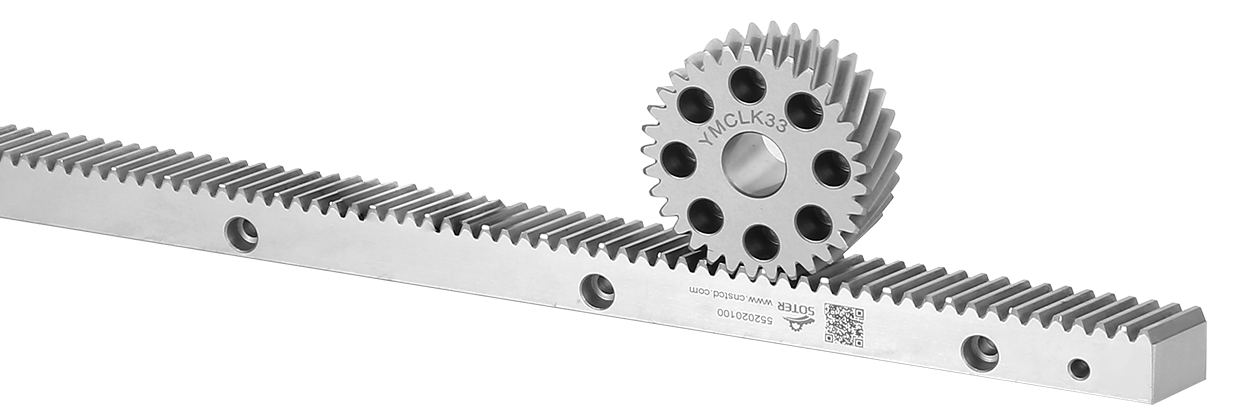

In modern mechanical systems, wear resistance is a critical factor in ensuring reliability, longevity, and precision. Linear motion components such as gear racks are subjected to repeated contact, high loads, and continuous movement. Without adequate wear resistance, gear teeth may deform or wear prematurely, causing backlash, reduced positional accuracy, and system failure. Surface hardening has become an essential method for improving the durability of a Precision Gear Rack, allowing it to maintain performance in demanding industrial applications.

Surface hardening involves modifying the properties of the outer layer of a gear rack while preserving the toughness and ductility of the core material. Common techniques include:

These processes increase surface hardness and wear resistance while maintaining the core’s ability to absorb loads and shocks.

Surface hardening improves wear performance through several mechanisms:

These factors collectively contribute to longer service life and more reliable operation.

Applying surface hardening to a Precision Gear Rack yields several tangible advantages:

These benefits are particularly important in high-performance machinery where consistent motion and durability are essential.

To achieve the results, engineers must address several critical aspects:

Attention to these details ensures the treated gear rack performs reliably under demanding conditions.

Surface hardening significantly enhances the wear resistance of a Precision Gear Rack by increasing surface hardness, minimizing deformation, and improving fatigue strength. Treatments such as carburizing, nitriding, and induction hardening allow gear racks to maintain precise tooth geometry, endure high loads, and operate reliably in industrial environments. Proper material selection, treatment uniformity, and post-processing finishing are essential to improve durability and performance. By implementing these measures, engineers can ensure that gear racks deliver consistent, long-term service, reducing maintenance costs and supporting high-precision mechanical systems.