Oct 17, 2025

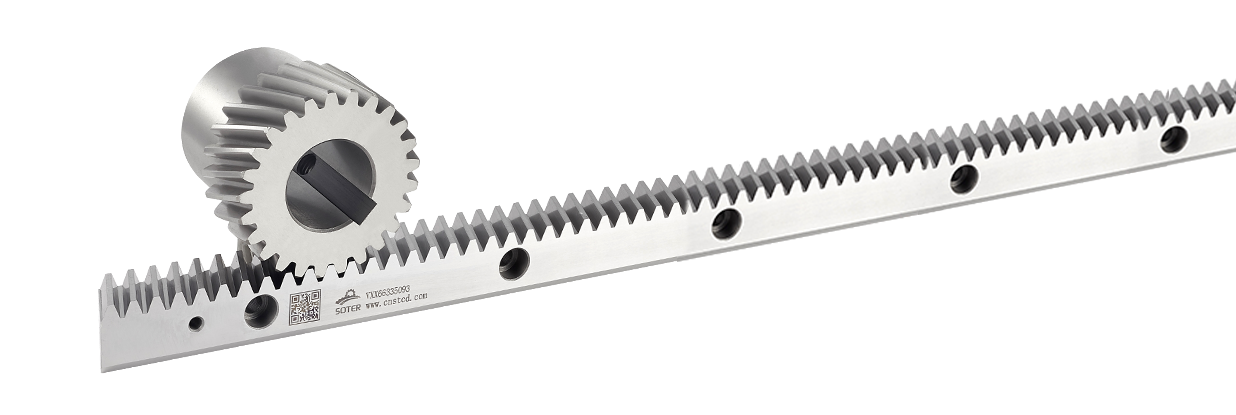

Mechanical components in industrial applications often operate under challenging conditions such as high humidity, dust, and contaminants. These environments can accelerate wear, cause corrosion, and reduce the overall lifespan of critical parts. Gear racks, which are essential for linear motion in machines such as CNC systems, robotic arms, and automated conveyors, are particularly vulnerable to these stresses. Understanding how a Precision Gear Rack performs under such conditions is vital for ensuring reliability and reducing maintenance requirements.

Dust accumulation is a common issue in factories, woodworking shops, mining operations, and outdoor environments. Dust particles can:

Excess moisture or high humidity presents additional challenges for gear racks:

Selecting corrosion-resistant materials, applying anti-rust coatings, and using sealed bearings or housings are essential strategies for maintaining durability in humid conditions.

To enhance durability under harsh conditions, several factors are critical:

These measures collectively ensure that the gear rack can withstand challenging operating conditions.

Even with a robust design, regular maintenance is crucial for long-term durability:

By implementing these practices, operators can significantly extend the life of the gear rack and maintain system performance.

In real-world industrial applications, a well-designed Precision Gear Rack can maintain high performance even in dusty, humid, or corrosive environments. Heavy-duty machinery in woodworking, mining, and outdoor automation demonstrates that appropriate material selection, surface treatment, and maintenance practices allow gear racks to function reliably over extended periods. These considerations are crucial for high-precision systems where linear motion consistency is essential.

Operating a Precision Gear Rack in harsh environments, such as high humidity or dust-laden settings, presents significant challenges. Abrasive wear, corrosion, and lubrication degradation are the primary concerns affecting durability. However, with careful material selection, surface treatments, precise manufacturing, and rigorous maintenance practices, these gear racks can maintain reliable performance and long service life. Understanding the environmental factors and adopting protective strategies ensures that the gear rack continues to meet the demanding requirements of industrial and automated systems, even under adverse conditions.