Jan 02, 2026

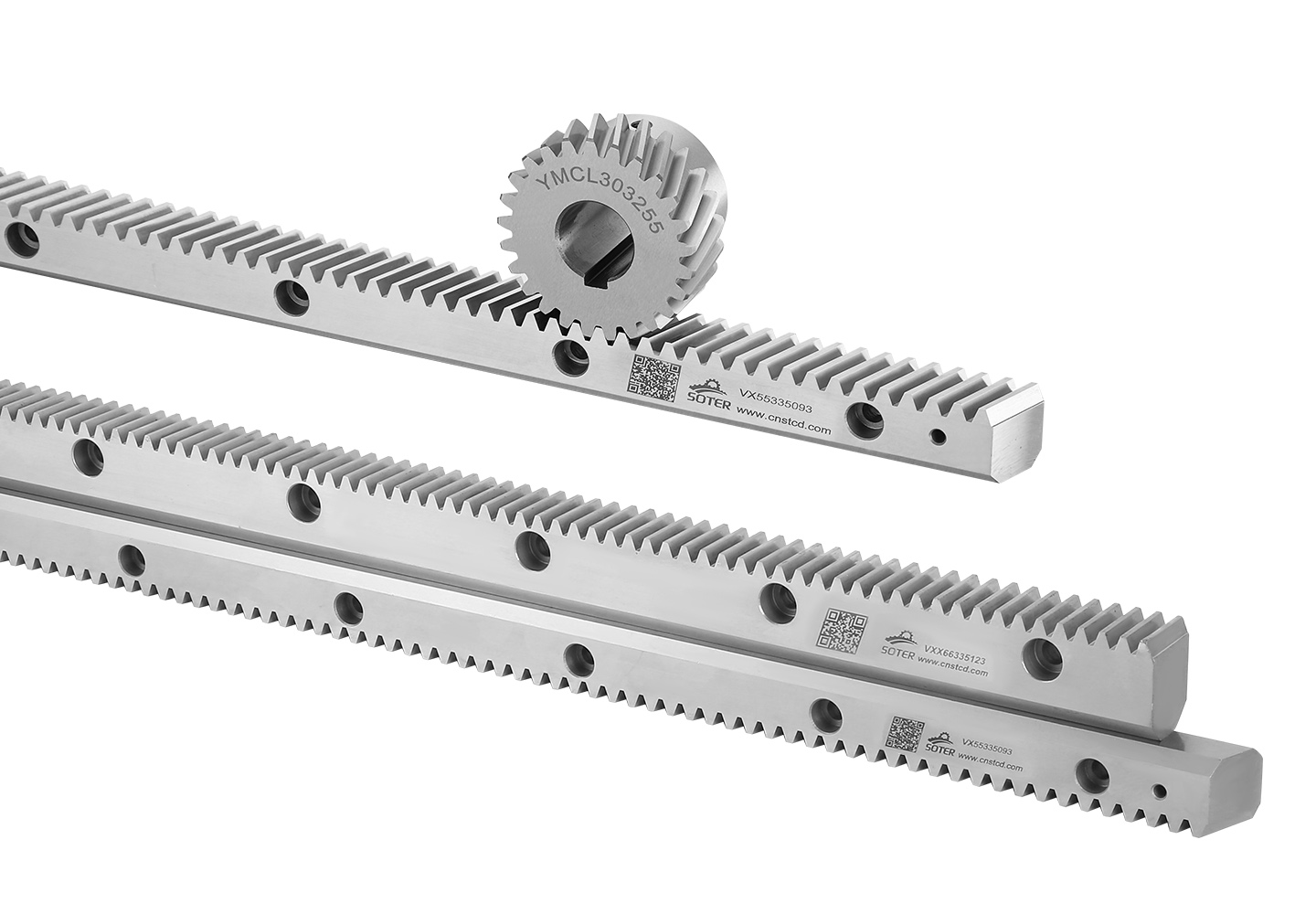

When a Rack And Pinion Linear Slide operates under heavy load conditions, the mechanical stresses on the rack, pinion, and guiding components increase significantly. This elevated stress environment can quickly reveal weaknesses in material properties, lubrication quality, alignment, and structural rigidity. Heavy loads amplify contact pressure on the meshing teeth and on the slide’s supporting mechanisms, increasing the possibility of wear, deformation, or binding. In such systems, maintaining load capacity is not simply about strength but about how well the slide can preserve dimensional stability while resisting impact forces, cyclic loads, and side loads imposed during operation.

One of the common failure modes under high load is accelerated tooth wear. When heavy loads generate excessive contact stress, the hardened surfaces of the rack and pinion begin to experience micro-pitting and abrasion. As sliding action continues, this surface damage evolves into deeper pitting, scoring, or even the flaking of material from the tooth flanks. Tooth wear changes the effective geometry of the mesh, causing backlash, noise, and reduced positional accuracy. In severe cases, the system may develop uneven tooth loading, which further intensifies localized wear. Without timely lubrication and surface protection, tooth degradation quickly becomes a progressive failure mechanism.

Under sustained heavy loads, the rack bar or guide rail can undergo bending deformation. Even small deflections negatively affect linear accuracy and may cause the pinion to engage improperly with the rack. Structural distortion also impacts the slide carriage, creating uneven contact across bearing surfaces. When deformation occurs repeatedly under cyclic loads, fatigue cracks form at stress concentration areas such as the root of the rack teeth or the mounting holes of the slide body. These cracks grow with each cycle until material integrity is compromised, causing partial tooth breakage or failure of the sliding carriage.

Another severe failure mode is the shearing or chipping of rack teeth, typically caused by sudden impact loads or repetitive overloading beyond design limits. Heavy loads increase the torque applied to the pinion, pushing the rack teeth toward shear failure. If the material hardness is insufficient or if heat treatment is inconsistent, the tooth root becomes the weak point and fractures. Tooth breakage often occurs abruptly and can cause system jamming, immediate shutdown, or secondary damage to surrounding components. For applications involving shock loads or emergency stops, reinforced materials and robust heat treatment processes are essential to reduce this risk.

Heavy loads also place significant stress on the guiding elements of the slide, such as linear bearings or roller blocks. Under excessive force, bearings may experience brinelling, where rolling elements indent the raceways, causing rough motion and unwanted vibration. Once brinelling occurs, the slide loses smoothness and may bind or stall during travel. Additionally, inadequate lubrication under high pressure accelerates bearing seizure. Misalignment caused by structural deformation further adds uneven load distribution, which quickly overloads individual bearings, ultimately resulting in complete mechanical failure of the slide assembly.

High load conditions generate elevated frictional heat in both the rack-pinion interface and the guide bearings. Increased temperature reduces lubricant viscosity, weakening the system’s protective film. As lubrication breaks down, metal-to-metal contact occurs, speeding up wear and frictional losses. Thermal expansion of components worsens meshing errors and causes binding. Over time, heat-induced lubrication failure becomes a cascading issue that accelerates wear and reduces overall system lifespan.

Preventing these failure modes requires proper material selection, surface hardening, structural reinforcement, and a precise alignment process. Regular lubrication, load monitoring, and periodic inspection of tooth profiles also play vital roles. By understanding how heavy loads affect linear slide performance, engineers can design systems that deliver reliable operation even in demanding industrial environments.