Dec 05, 2025

Rack and pinion systems are widely utilized in automotive steering, industrial machinery, robotics, and automation applications. The accuracy of the gear tooth profile directly impacts motion precision, load distribution, wear characteristics, and noise levels. Even minor deviations in the tooth geometry can cause uneven wear, increased backlash, vibration, and premature failure of the components. For Rack And Pinion Suppliers, maintaining strict control over tooth profile accuracy is essential to meet customer requirements, guarantee reliable performance, and ensure long-term durability. A well-controlled production process not only enhances functionality but also reduces maintenance costs and improves overall system efficiency.

Material choice forms the foundation for achieving precise tooth profiles. High-quality steel alloys or advanced polymers with uniform microstructures are preferred due to their dimensional stability and resistance to deformation during machining, heat treatment, and operational stress. Inconsistent materials can warp or distort under mechanical or thermal load, causing deviations in tooth shape and reducing the accuracy of the rack and pinion system. By ensuring consistent material properties, suppliers create a stable baseline that supports precise machining and reliable long-term performance. Proper material selection also helps in achieving uniform hardness after heat treatment, reducing the risk of differential wear that could compromise gear accuracy.

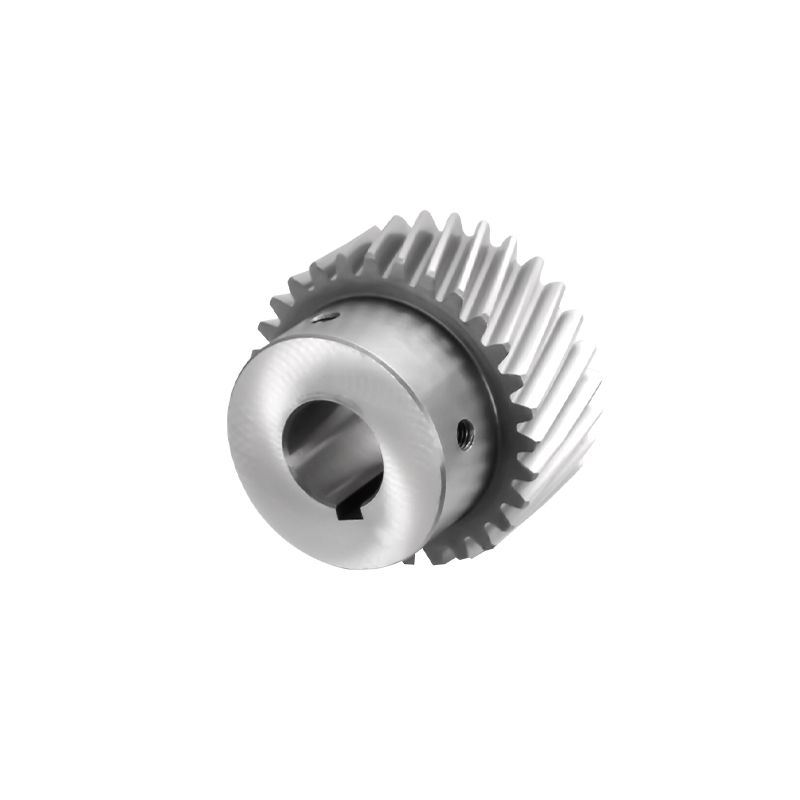

Precision in tooth geometry is largely dependent on the machining methods employed. Common techniques used by Rack And Pinion Suppliers include gear hobbing, shaping, and grinding, each offering different levels of precision. Hobbing is efficient for medium to high-volume production and provides good accuracy for standard applications, while gear grinding allows for extremely tight tolerances required in high-performance or precision-driven systems. CNC-controlled machines and precision fixtures further enhance repeatability, ensuring each tooth is shaped consistently. Accurate control over cutting parameters such as feed rate, cutting speed, and tool engagement is critical to decrease residual stresses and prevent minor deviations in tooth profile that could affect meshing performance.

Detecting and verifying tooth profile accuracy involves sophisticated inspection techniques. Gear measuring machines (GMM), coordinate measuring machines (CMM), and optical or laser-based systems are commonly employed to measure critical parameters, including tooth thickness, pitch, flank geometry, and involute accuracy. Optical comparators and laser scanners allow non-contact inspection, capturing detailed surface profiles and detecting minor deviations that could impair operational performance. Multi-stage inspections, from rough machining to final finishing, help identify errors early, allowing corrective actions before components leave the production line. This layered inspection approach ensures high-quality output with risk of defective parts reaching customers.

Controlling tooth profile accuracy extends beyond detection to proactive process management. Machining parameters, tool wear, environmental conditions, and heat treatment processes must be closely monitored and adjusted to maintain precision. Heat treatment, including quenching and tempering, is carefully controlled to reduce distortion and retain dimensional stability. Statistical process control (SPC) methods are often applied to track variations, identify trends, and implement corrective actions in real time. Feedback from measurement data allows manufacturers to fine-tune production parameters, ensuring consistent quality across batches. Combining process optimization with rigorous inspection practices guarantees that racks and pinions meet stringent tolerances and functional requirements.

Maintaining precise tooth profiles is critical for the performance, reliability, and longevity of rack and pinion systems. By selecting high-quality materials, employing advanced machining techniques, implementing rigorous measurement protocols, and optimizing production processes, Rack And Pinion Suppliers can consistently deliver components with good accuracy. These measures not only enhance operational efficiency and reduce wear but also strengthen customer confidence in the performance and durability of rack and pinion systems across diverse applications.