Aug 26, 2025

Introduction to the Load Capacity of Straight Gear Rack

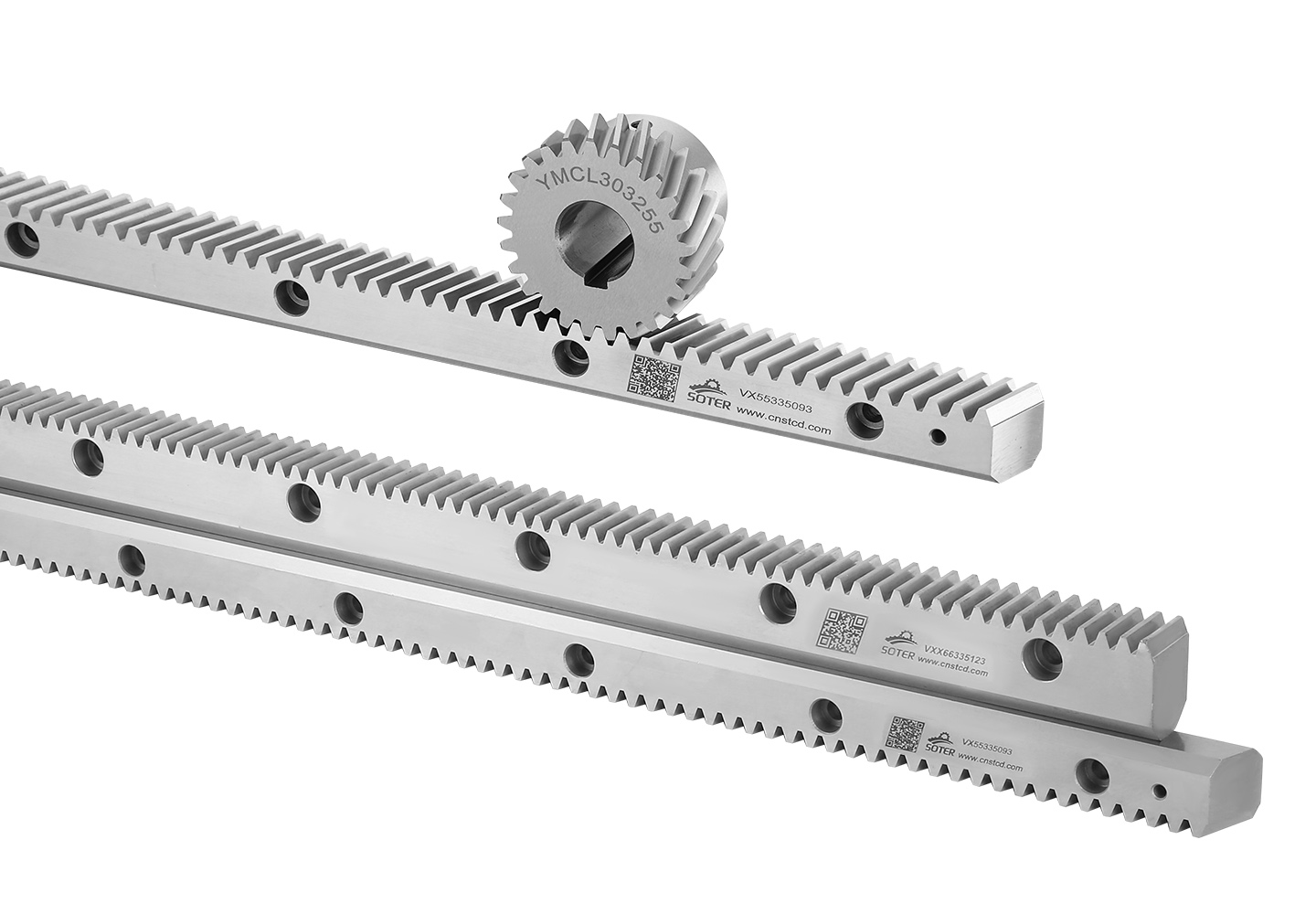

The load capacity of a Straight Gear Rack is a fundamental parameter that determines its suitability in mechanical and industrial applications. This type of gear rack is widely used in linear motion systems, heavy machinery, and automation equipment due to its simplicity and efficiency. Understanding the load capacity helps engineers and designers select the appropriate rack for specific tasks, ensuring safety, reliability, and performance. The load capacity essentially refers to the force or weight the gear rack can support during operation without failure or excessive wear.

Material Influence on Load Capacity

One of the primary factors affecting the load capacity of a Straight Gear Rack is the material used in its construction. Commonly, gear racks are manufactured from high-strength steel alloys that offer good hardness and durability. Heat treatment processes, such as carburizing or nitriding, are often applied to improve surface hardness and resistance to wear. These treatments increase the gear teeth’s ability to withstand high loads and reduce the risk of deformation under pressure. The choice of material and treatment directly impacts how much load the gear rack can safely carry over its service life.

Design Factors Affecting Load Bearing

The geometric design of the Straight Gear Rack also plays a critical role in its load capacity. Parameters such as tooth profile, module size, and pitch influence the way forces are distributed across the rack and the mating pinion. Larger modules generally mean larger teeth and wider contact areas, which allow the gear rack to handle higher loads by spreading forces more evenly. Moreover, the straight tooth design facilitates direct engagement with the pinion, which can improve load transmission efficiency. However, it may also result in higher noise and vibration compared to other types, like helical racks.

Installation and Operational Conditions

Proper installation and alignment are essential to achieving the rated load capacity of a Straight Gear Rack. Misalignment or improper mounting can cause uneven load distribution, which can cause premature wear or mechanical failure. Additionally, operating conditions such as speed, temperature, and lubrication affect the gear rack’s ability to carry loads. Adequate lubrication reduces friction and wear between the gear teeth, directly influencing load capacity and operational lifespan. Environmental factors, including exposure to contaminants or corrosive agents, may also affect performance if not properly addressed through protective coatings or maintenance.

Load Capacity in Different Applications

Straight Gear Racks are commonly used in applications ranging from material handling systems to CNC machinery. Their load capacity must be matched to the demands of the application to ensure efficiency and safety. For example, in heavy lifting or industrial automation, racks with higher load capacities and robust construction are required. Conversely, lighter loads in precision equipment may permit the use of smaller, more compact racks. Engineers must consider dynamic loads, shock loads, and duty cycles to select a rack that meets the operational requirements without risking failure.

Conclusion on Load Capacity Considerations

The load capacity of a Straight Gear Rack depends on a combination of material quality, design parameters, installation precision, and operational environment. Selecting the right gear rack involves balancing these factors to meet the specific needs of the application. Proper maintenance and careful monitoring of operating conditions further help in preserving the load capacity over time. Understanding these elements ensures that the gear rack performs reliably and contributes to the overall efficiency of mechanical systems.