Aug 22, 2025

Flexibility in Length Design for Specialized Applications

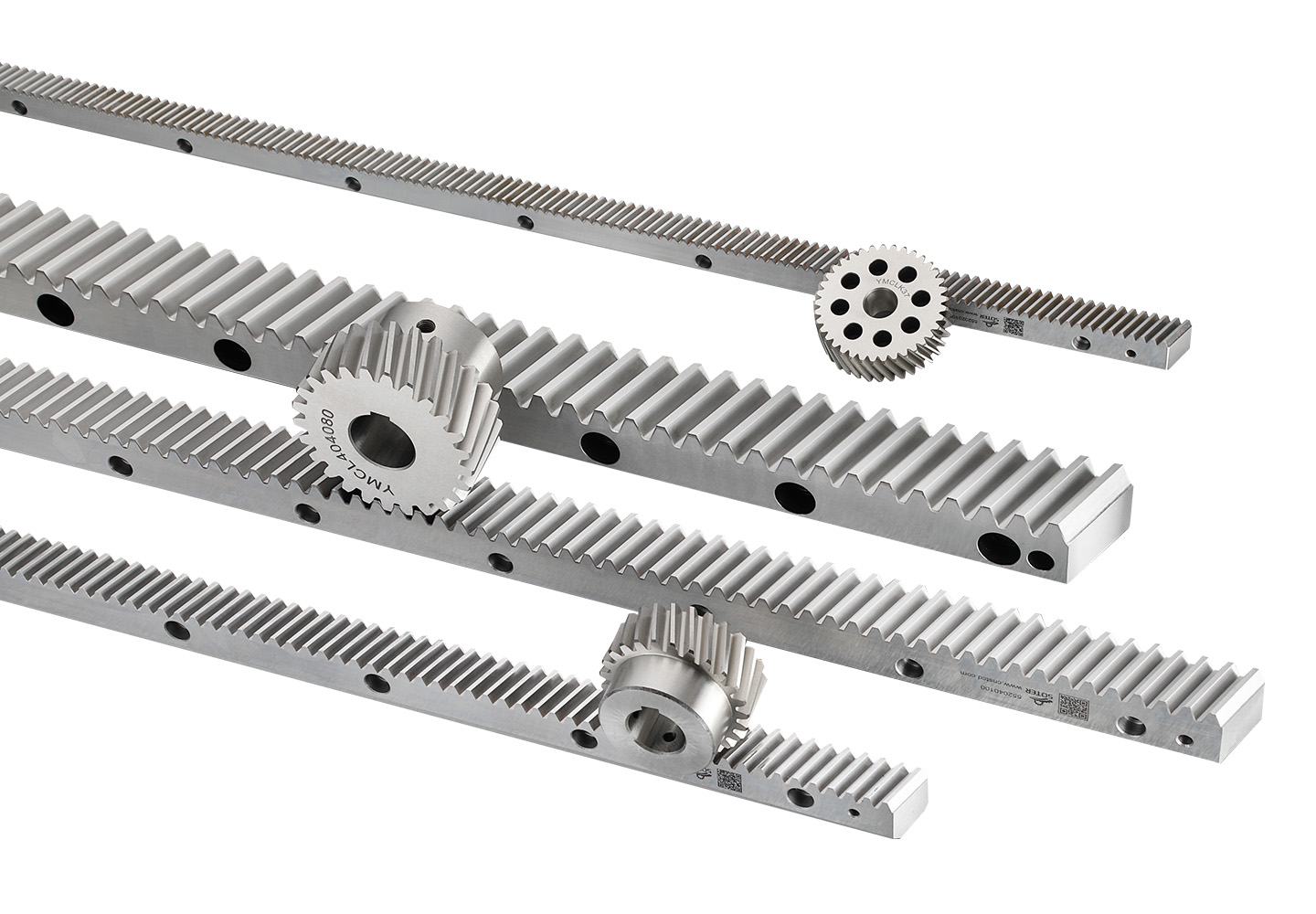

The ability to customize the length of a Straight Gear Rack is essential in meeting the diverse needs of modern machinery and industrial equipment. Standard gear racks often come in fixed lengths, such as 500mm, 1000mm, or 2000mm, but these do not always suit specific design requirements. Fortunately, many manufacturers offer custom length services, enabling seamless integration into larger or uniquely shaped systems. This flexibility allows for continuous linear motion across long travel distances without compromising precision. When gear racks need to be joined end-to-end, careful machining ensures tooth alignment and pitch consistency, which is critical for maintaining smooth motion in applications like gantry systems, automation lines, or large-scale CNC machines.

Adaptation of Tooth Profiles to Match Technical Demands

In addition to customizable length, the tooth profile of a Straight Gear Rack can also be tailored to meet performance or compatibility needs. While standard racks typically use straight involute teeth designed to mesh with standard pinions, certain applications may require non-standard profiles. Custom tooth shapes can optimize torque transmission, reduce backlash, or accommodate non-standard gear pitch diameters. For instance, applications with high precision demands may benefit from ground teeth and tighter tolerances, while heavy-load systems might require deeper tooth cuts or reinforced profiles. This adaptability ensures that gear racks can serve a wide variety of operational environments, from high-speed automation to rugged mechanical systems.

Material and Surface Finish Options for Custom Builds

Custom Straight Gear Rack production doesn’t stop at length and tooth design—material selection and surface treatment are also key elements in supporting specialized applications. Depending on the operating environment, customers can choose from various materials such as carbon steel, alloy steel, stainless steel, or even engineering plastics. Further customization is possible through heat treatments like carburizing or induction hardening, which improve surface wear resistance, and surface finishes like black oxide, zinc plating, or chrome coating, which offer corrosion protection. These enhancements allow customized gear racks to operate reliably in environments exposed to moisture, chemicals, or heavy wear.

Manufacturing Capabilities and Order Quantities

One of the concerns for companies considering customized gear components is whether such flexibility is economically feasible, especially for small batch orders. Fortunately, advancements in CNC machining, gear hobbing, and digital modeling have made it more cost-effective to produce custom gear racks without the need for mass production. Manufacturers often work with customers from the design stage to ensure that the final product meets exact specifications, whether for a single prototype or a limited production run. This approach is particularly useful in industries like aerospace, robotics, and special-purpose machinery, where off-the-shelf components rarely meet all operational criteria.

A Versatile Solution for Custom Engineering Requirements

The Straight Gear Rack offers a high degree of customization in both length and tooth profile, making it a practical solution for applications with non-standard requirements. Whether the need is for extended travel length, special tooth geometry, enhanced load capacity, or corrosion resistance, modern manufacturing processes enable gear racks to be tailored precisely to fit those needs. This versatility reinforces their value in complex engineering systems where flexibility and performance go hand in hand.