May 02, 2025

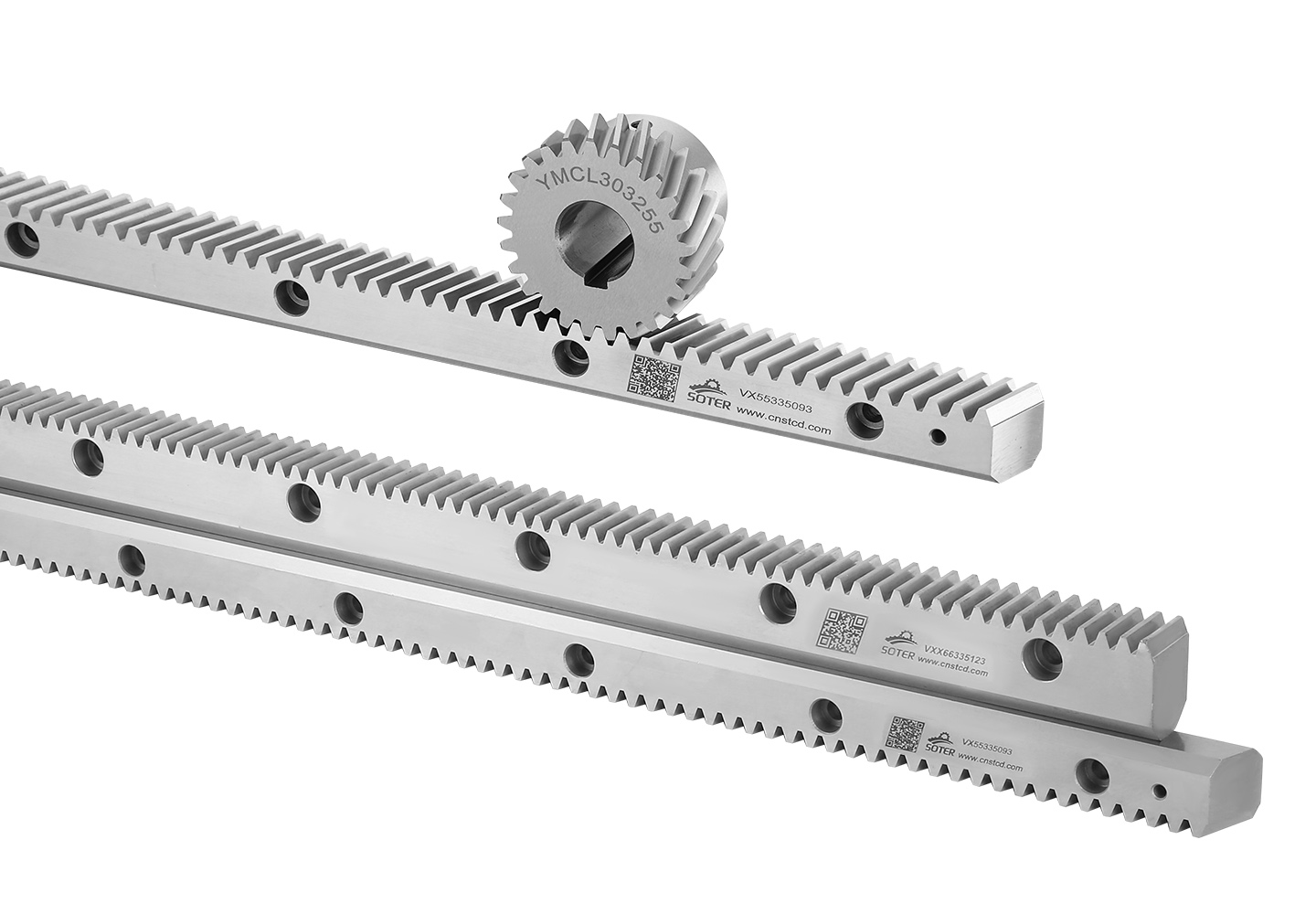

Within the industrious environment of the Helical Toothed Gear Racks Factory, the integrity of gear teeth is paramount for the efficient operation of machinery. Wear and tear are inevitable in such high-precision manufacturing facilities, and the Helical Toothed Gear Racks Factory must be adept at restoring the teeth of their gear racks to maintain suitable performance. The process of repairing worn teeth in helical toothed gear racks is a meticulous task that requires a deep understanding of material science, engineering principles, and the specific challenges faced by Helical Toothed Gear Racks Factory.

The wear of teeth in helical toothed gear racks can result from various factors, including friction, load, and operational stresses. As these wear patterns emerge, the Helical Toothed Gear Racks Factory must employ a range of repair techniques to restore the gear racks to their original condition. One of the primary methods involves the use of metal spraying, where a new layer of material is applied to the worn teeth to rebuild their shape and size. This technique is particularly effective in the Helical Toothed Gear Racks Factory due to its ability to create a durable and wear-resistant surface.

Another repair method is the application of hard-facing, where a harder material is welded onto the worn teeth to increase their resistance to further wear. This process is crucial in the Helical Toothed Gear Racks Factory, as it not only restores the gear racks but also enhances their longevity and resistance to future wear. The hard-facing materials used must be carefully selected to ensure compatibility with the original gear material and to provide the necessary wear resistance.

In some cases, the Helical Toothed Gear Racks Factory may opt for a more invasive approach, such as grinding or machining the worn teeth to remove the worn material and create a new, undamaged surface. This method requires precise machinery and skilled operators to ensure that the gear tooth profiles are accurately restored. The Helical Toothed Gear Racks Factory must invest in high-quality equipment and regular maintenance to keep their gear racks in good condition.

For severe wear or damage, the Helical Toothed Gear Racks Factory may need to replace individual teeth or entire sections of the gear rack. This process involves removing the damaged parts and installing new ones that are either manufactured in-house or sourced from reputable suppliers. The Helical Toothed Gear Racks Factory must ensure that these replacements are of high quality to maintain the performance and reliability of their gear racks.

Regular inspection and maintenance are also key components in the Helical Toothed Gear Racks Factory's strategy for managing wear. By monitoring the condition of gear teeth and addressing minor issues before they become major problems, the factory can prevent unnecessary wear and extend the life of their gear racks. This proactive approach is essential for maintaining efficiency and reducing downtime in the Helical Toothed Gear Racks Factory.

In conclusion, the Helical Toothed Gear Racks Factory must employ a multifaceted approach to the repair of worn teeth in their gear racks. This includes a combination of advanced material application techniques, precision machining, component replacement, and vigilant maintenance. By staying at the forefront of repair technology and prioritizing the quality of their gear racks, the Helical Toothed Gear Racks Factory can ensure that their products remain reliable and efficient, even under demanding conditions.