Aug 01, 2025

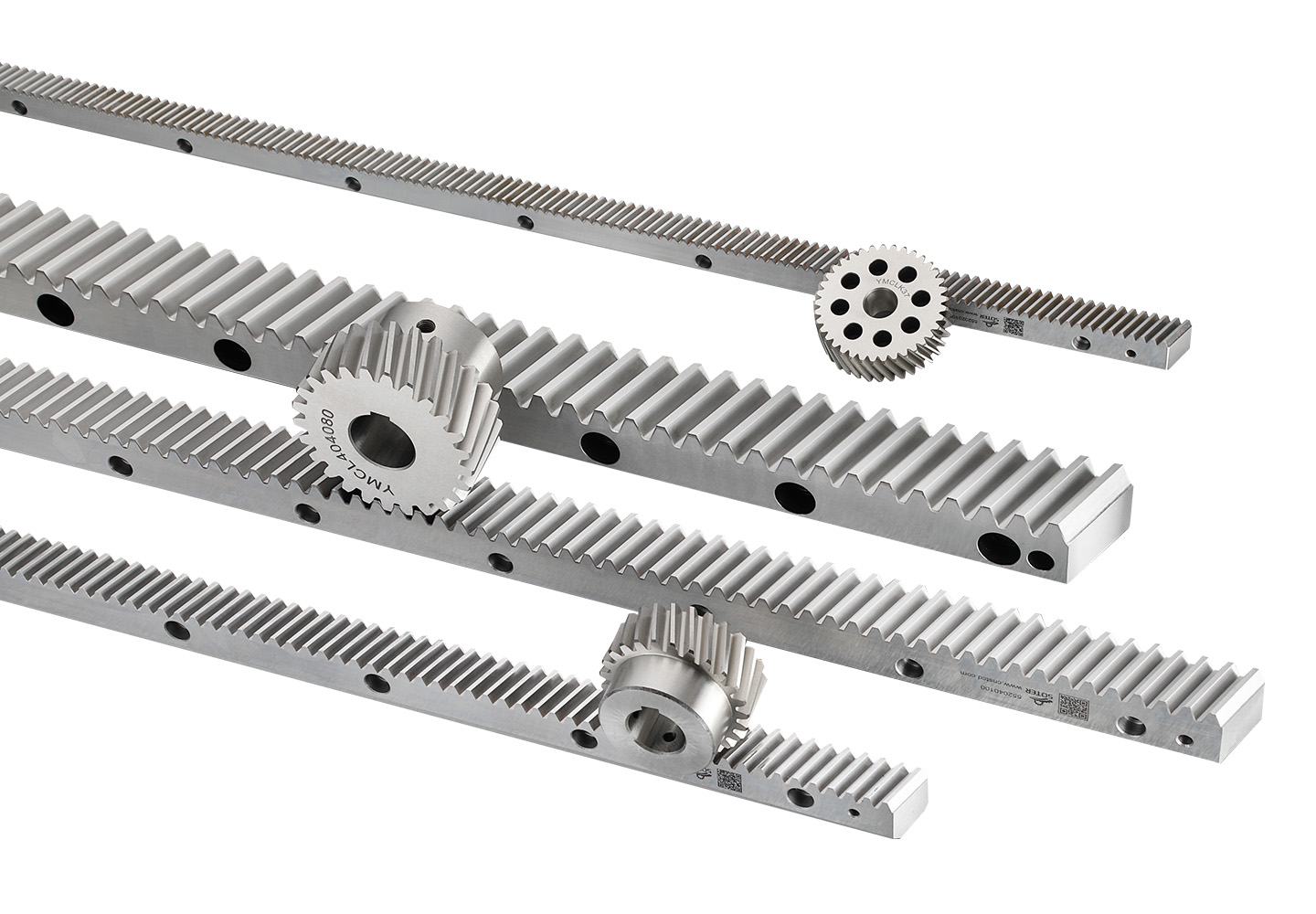

In mechanical systems requiring precise linear motion, both helical gear racks and straight gear racks are commonly used. While each type has its own merits, it offers several distinct advantages over the straight gear rack that make it preferable in many demanding applications. This article explores the key benefits of them compared to straight gear racks.

Smoother and Quieter Operation

One of the significant advantages of a helical gear rack lies in the design of its teeth. Unlike straight gear racks, which have teeth cut perpendicular to the rack’s length, they feature angled teeth arranged in a helix pattern. This angled tooth engagement allows for gradual and continuous contact between the rack and the mating gear.

The gradual engagement reduces the impact forces that occur when teeth mesh, resulting in smoother transmission of motion and significantly reduced noise and vibration. This makes helical gear racks ideal for applications where quiet and smooth operation is essential, such as robotics, CNC machinery, and automotive systems.

Higher Load Capacity and Strength

The angled teeth of a helical gear rack increase the contact ratio — the number of teeth engaged at any one time — compared to a straight gear rack. This greater tooth engagement spreads the load across multiple teeth rather than concentrating it on just one or two.

As a result, they can carry higher loads and transmit greater power without excessive wear or failure. This characteristic improves durability and allows the gear rack to perform reliably in heavy-duty and high-speed applications.

Improved Wear Resistance and Longevity

Due to the more even load distribution and reduced shock loading, helical gear racks generally exhibit better wear resistance than straight gear racks. The gradual tooth engagement lowers peak stresses on the tooth surfaces, reducing surface fatigue and tooth flank pitting.

This causes extended service life and reduces maintenance frequency and costs. In environments where longevity and reliability are critical, it offers a clear advantage.

Better Handling of High-Speed Applications

Helical gear racks are better suited to high-speed operations than straight gear racks. The smooth meshing and reduced vibration help maintain precise positioning and reduce the risk of gear tooth damage at high speeds.

Straight gear racks, by contrast, can generate more noise and vibration under rapid movement, which can cause premature wear or mechanical issues. Thus, the helical gear rack is often the preferred choice for fast, accurate linear motion systems.

Enhanced Load Transmission Efficiency

The continuous contact of the angled teeth in a helical gear rack improves transmission efficiency by reducing energy losses associated with impact and vibration. This efficiency translates to smoother motion control, lower operating temperatures, and improved overall system performance.

While helical gear racks do introduce some axial thrust forces due to the helix angle, these can be managed with proper bearing selection and system design, making the trade-off worthwhile in many applications.

Considerations and Trade-offs

Despite these advantages, they can be more complex and costly to manufacture compared to straight gear racks. The angled teeth require more precise cutting and finishing processes.

Additionally, the axial thrust generated by the helix angle necessitates adequate support to prevent undue wear on bearings and other components. Nevertheless, the performance benefits often outweigh these challenges in demanding mechanical systems.