Sep 12, 2025

The Role of Load Capacity in Mechanical Systems

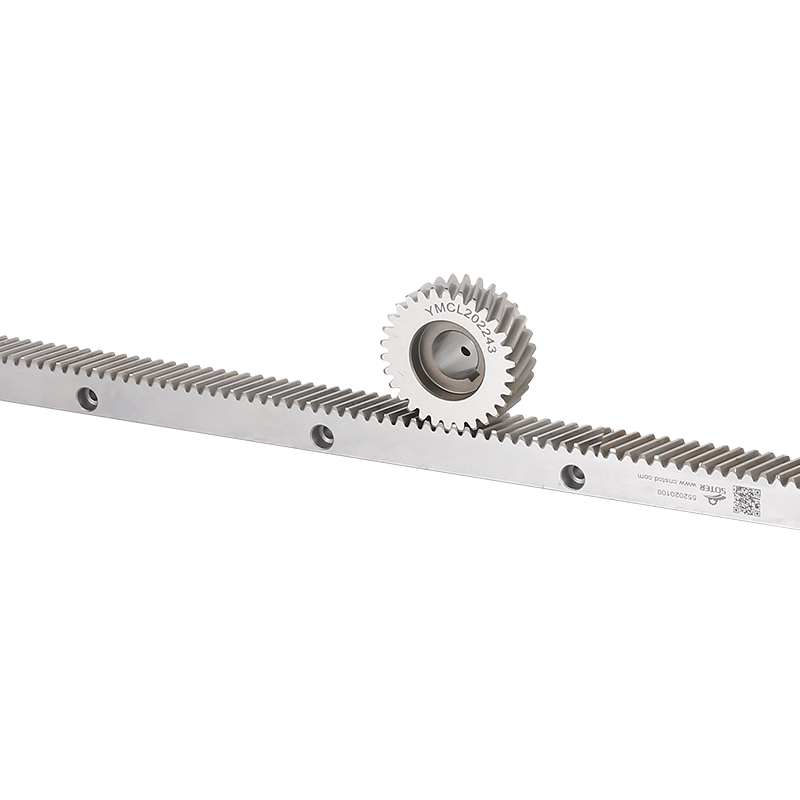

In industrial machinery and automation equipment, the ability of transmission components to withstand heavy loads directly influences reliability and service life. When systems are required to handle significant forces, the mechanical components that translate motion must be capable of enduring stress without deformation or premature wear. This is particularly true in applications such as large CNC machines, heavy-duty automation lines, construction equipment, and mining machinery. For such applications, the Precision Gear Rack is frequently implemented due to its ability to deliver accurate linear motion while simultaneously supporting substantial loads. Evaluating its performance under these demanding conditions provides valuable insight into its practical capabilities.

Structural Design for High Load Resistance

The structural design of gear racks is a fundamental factor in determining their load-bearing capacity. Tooth geometry, module size, and surface finish all contribute to how effectively the rack can handle pressure from the mating pinion. Heavier loads generate higher contact stresses between teeth, which can cause fatigue if not managed properly. Precision-manufactured racks are designed with carefully calculated profiles that distribute forces evenly across tooth surfaces, reducing localized stress concentrations. This uniform distribution of load is critical for maintaining both strength and smooth motion under heavy-duty conditions.

Material Strength and Heat Treatment

Another essential factor affecting load capacity is the choice of material. Gear racks intended for heavy loads are often made from alloy steels with high tensile strength and fatigue resistance. To further enhance their ability to resist wear and deformation, these racks undergo processes such as induction hardening, carburizing, or nitriding. Such treatments increase surface hardness while maintaining a tough, resilient core, allowing the gear rack to resist pitting, scuffing, and cracking even when exposed to continuous heavy loads. The balance between hardness and ductility is crucial to ensure long service life without brittleness.

Influence of Lubrication and Operating Conditions

Even with high-strength materials and precise manufacturing, proper lubrication plays a decisive role in enabling a gear rack to function effectively under heavy loads. Inadequate lubrication causes higher friction, excessive heat, and accelerated wear, all of which reduce load capacity. Industrial systems typically use specialized lubricants designed to maintain film strength under pressures. Additionally, environmental conditions such as temperature, dust, or exposure to corrosive agents also impact the load-bearing performance. When lubrication and protection are properly managed, the operational limits of a gear rack under heavy loads are significantly extended.

Comparison with Alternative Systems

While other transmission systems, such as ball screws or linear actuators, may offer advantages in specific contexts, gear racks are uniquely suited to heavy load applications. Ball screws are good for high precision at lighter loads, but can suffer reduced efficiency under very high forces. Hydraulic systems can generate immense force but often lack the positioning accuracy required for precision machining. The rack and pinion system, however, provides a balanced solution: high load-bearing capacity combined with accurate, repeatable linear motion, making it a suitable choice where both strength and precision are required.

Practical Applications in Industry

Industries such as steel manufacturing, aerospace tooling, and large-scale construction frequently demand equipment capable of bearing high loads. In these environments, racks must not only support the direct weight of machinery components but also absorb dynamic forces generated during rapid acceleration, deceleration, and impact conditions. Precision-engineered gear racks have proven capable of handling such environments without compromising accuracy. Their durability and strength make them indispensable in systems where reliability under heavy loads is not just beneficial but essential.

The load-bearing capacity of gear racks under heavy-duty conditions is a product of precise engineering, material science, and proper operational practices. By combining optimized tooth geometry, advanced heat treatments, and effective lubrication, these components deliver both strength and accuracy. Compared with alternative transmission methods, they represent a versatile and robust choice for applications where high loads and precise motion coexist. Their proven performance across industries underscores their critical role in modern heavy-duty mechanical systems.