Nov 21, 2025

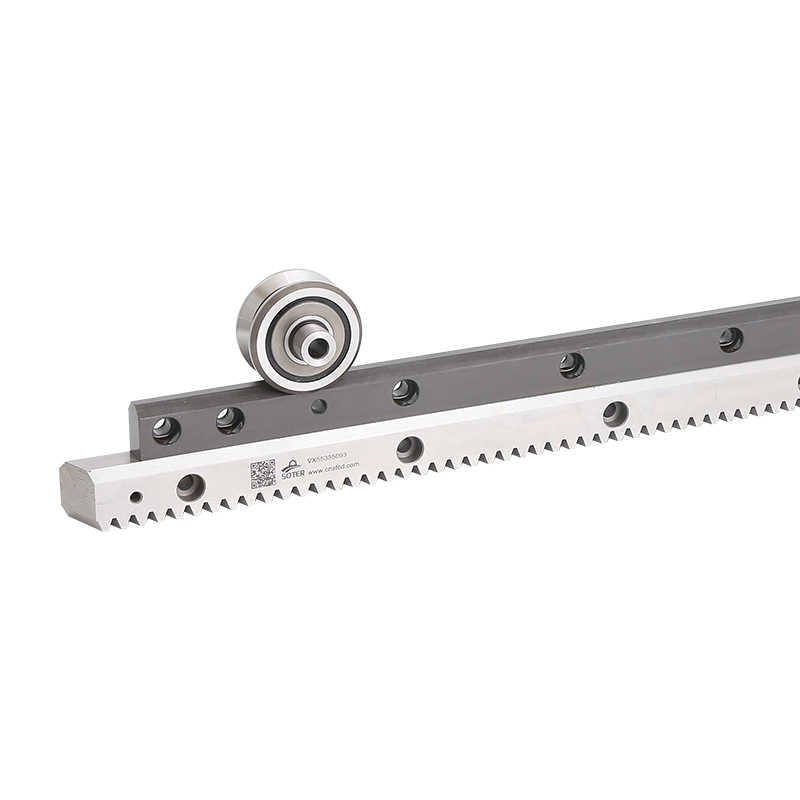

The stability and performance of mechanical systems rely heavily on the accuracy of their components. Among these, the Precision Gear Rack plays a critical role in linear motion and power transmission applications. Its manufacturing precision directly affects operational smoothness, load distribution, and overall system reliability. Even minor deviations in tooth geometry, spacing, or alignment can cause significant performance issues, including vibration, backlash, uneven wear, and reduced lifespan of connected components. Understanding the relationship between gear rack accuracy and system stability is essential for designers, manufacturers, and operators aiming to achieve high-performance machinery.

The geometry of gear teeth, including profile shape, pressure angle, and tooth spacing, determines how loads are transmitted between the gear rack and its mating pinion. Accurate tooth profiles ensure uniform contact and proper load distribution along the entire tooth surface. When a gear rack deviates from its design specifications, localized stress concentrations can occur, causing accelerated wear, surface fatigue, and potential tooth failure. High-precision gear racks reduce these issues, ensuring that forces are evenly distributed, which contributes to smoother operation and enhanced system stability under both light and heavy loads.

Backlash, or the slight gap between meshing gear teeth, is directly influenced by the manufacturing accuracy of a gear rack. Excessive backlash can result in delayed response, positional errors, and oscillation in precision machinery. Conversely, too little backlash can increase friction, heat generation, and wear. By producing a precision gear rack with tight tolerances, manufacturers can control backlash to suitable levels, ensuring consistent motion accuracy. This is particularly critical in applications such as CNC machines, robotics, and automated assembly systems, where even minor positional errors can cause quality defects or operational inefficiency.

Mechanical vibration and noise are common consequences of inaccuracies in gear rack fabrication. Uneven tooth spacing or inconsistent surface finish causes intermittent contact during meshing, resulting in oscillations and audible noise. Over time, this can affect not only the gear rack but also bearings, supports, and connected mechanical elements. Precision gear racks, manufactured with strict adherence to dimensional tolerances and smooth surface finishes, reduce vibration and noise levels, causing a more stable and quieter mechanical system. This stability is crucial for high-speed applications where vibration can compromise both performance and safety.

Manufacturing precision directly impacts wear patterns on the gear rack and mating pinion. Inaccurate teeth can create uneven pressure points, accelerating material degradation and reducing component lifespan. A high-precision gear rack ensures consistent tooth engagement, which reduces surface fatigue and prolongs service life. Reliable wear resistance not only improves long-term stability but also reduces maintenance frequency and operational downtime, contributing to higher system efficiency and cost-effectiveness.

The precision of a gear rack also affects the performance of the entire mechanical system. Accurate alignment facilitates seamless integration with other components, such as guides, bearings, and actuators. It ensures that linear motion remains smooth and predictable, preventing misalignment and mechanical stress in other parts of the system. For automated and high-speed machinery, maintaining system reliability through precise gear racks is essential to prevent unexpected failures and maintain consistent production quality.

The manufacturing accuracy of a Precision Gear Rack plays a vital role in the stability, efficiency, and longevity of mechanical systems. High-precision gear racks ensure proper load distribution, controlled backlash, reduced vibration, and consistent wear patterns, all of which contribute to smooth and reliable operation. By prioritizing gear rack precision, engineers and manufacturers can enhance system performance, extend component life, and maintain the overall stability of complex mechanical applications.