May 26, 2025

The Role of Precision in Mechanical Power Transmission

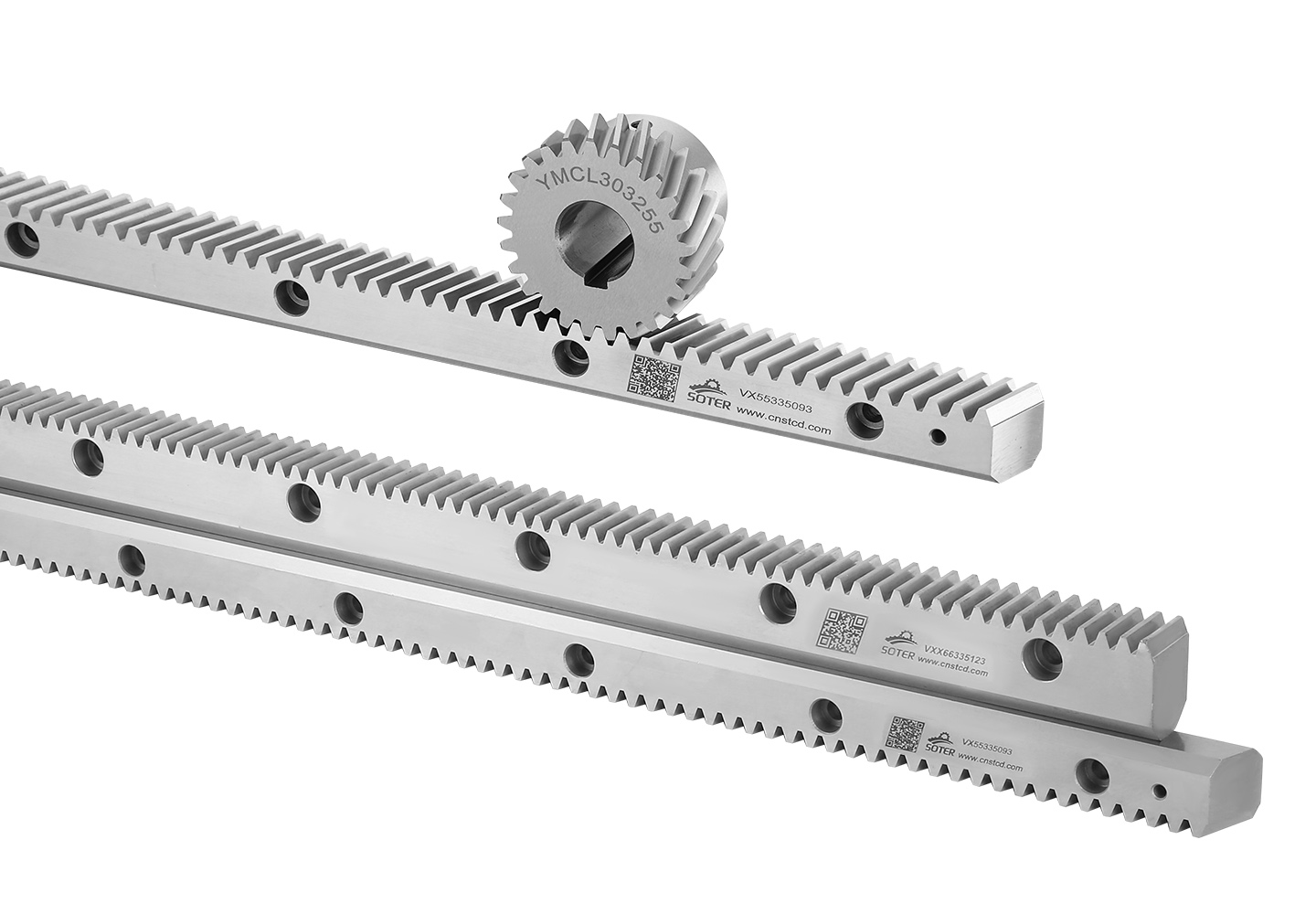

In gear systems, the efficiency of power transmission is closely tied to the quality and precision of the components involved. When considering rack and pinion mechanisms, especially those manufactured by a Helical Racks Factory, machining accuracy becomes a critical factor in determining overall system performance. Helical racks are favored in many industries due to their smoother motion, quieter operation, and greater load-bearing capabilities compared to straight racks. However, these advantages can only be fully realized if the components are produced with high machining precision.

Tooth Geometry and Contact Accuracy

The defining feature of a helical rack is its angled teeth, which are designed to engage with a pinion gear gradually rather than all at once. This angled engagement reduces noise and distributes load across multiple teeth simultaneously. For this engagement to be truly effective, the teeth must be cut to exact specifications. A Helical Racks Factory that maintains tight tolerances in tooth profile and spacing ensures that the gear teeth mesh well, reducing micro-slips and energy loss through friction or backlash. Any deviation from precise geometry can result in poor contact, misalignment, or uneven loading — all of which reduce transmission efficiency.

Surface Finish and Friction Reduction

Another key aspect of machining precision is the surface finish of the rack teeth. A smoother surface reduces friction during operation, which directly enhances mechanical efficiency. Helical racks with rough or uneven surfaces, often a result of low-precision manufacturing, tend to produce higher resistance as the pinion moves along the rack. This added resistance not only wastes energy but also contributes to increased wear and potential system failure over time. A Helical Racks Factory that employs advanced grinding and finishing technologies will produce components with good surface quality, causing more efficient and longer-lasting gear systems.

Consistency Across Production Batches

Precision in a Helical Racks Factory must be consistent across all units produced, particularly for systems that rely on multiple rack segments or require replacements over time. Inconsistencies between batches can result in alignment issues, which in turn impact the smoothness and accuracy of motion. High machining precision ensures that each rack segment matches seamlessly, allowing the transmission system to maintain its designed efficiency throughout its operational life.

Impact on Wear and Maintenance

Precision manufacturing also reduces the rate of wear on both the rack and the pinion. When teeth mesh cleanly and with the correct alignment, stress is distributed evenly across the contact area. This reduces localized pressure points and prolongs component life. A less precise rack, on the other hand, may cause uneven wear patterns, requiring more frequent maintenance or part replacement. In systems where downtime is costly, such as in automated industrial machinery, the benefits of a high-precision rack produced by a quality Helical Racks Factory are substantial.

Conclusion

Ultimately, the machining precision of products from a Helical Racks Factory has a profound effect on transmission efficiency. Precision ensures suitable tooth engagement, reduces friction and wear, and supports consistent system performance. For applications demanding reliability, longevity, and energy efficiency, selecting a manufacturer that prioritizes high machining standards is not just beneficial — it is essential.