May 23, 2025

Understanding the Fundamentals of Helical Rack Mechanics

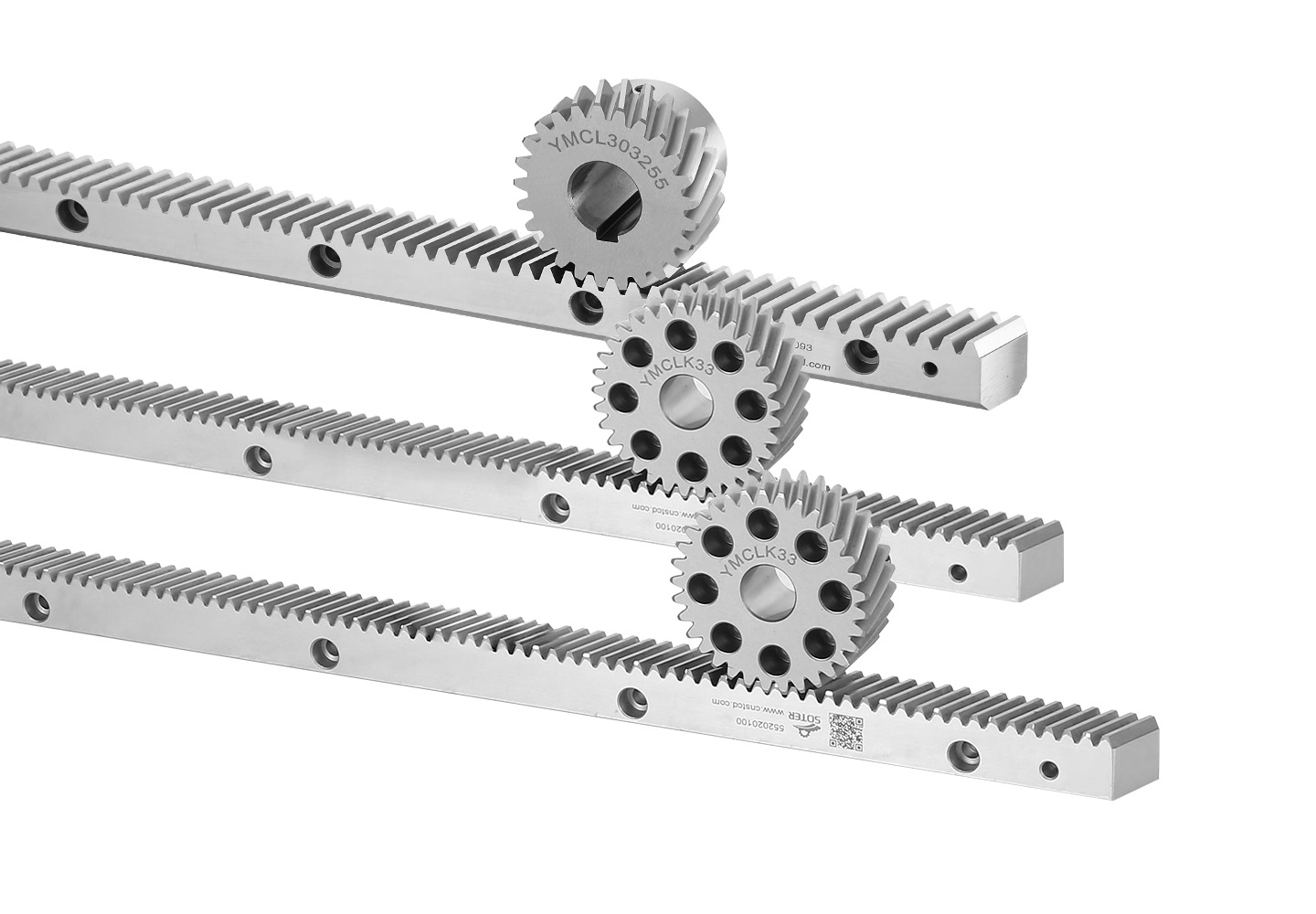

Helical racks are often associated with smooth and efficient horizontal motion systems, but many engineers and system designers also ask whether products from a Helical Racks Factory can be effectively used in vertical transmission applications. The core principle of a helical rack involves teeth cut at an angle to the axis, allowing for gradual meshing with a mating pinion. This design provides continuous tooth engagement, reduces noise, and reduces backlash. These same advantages also bring potential benefits when considering vertical motion transmission.

Performance in Vertical Motion Systems

Products manufactured by a reputable Helical Racks Factory can certainly be adapted for vertical applications, provided the design accounts for specific mechanical considerations. Vertical systems inherently involve gravity acting directly on the load, which adds a significant factor that the drive system must overcome and manage consistently. Helical racks, with their good tooth engagement and higher load distribution, can maintain stability and accuracy under vertical load conditions. The increased contact ratio between the helical teeth and the pinion allows for better load support than straight rack systems, which may be more prone to slippage or uneven wear when used vertically.

Load Retention and Backdriving Considerations

A key challenge in vertical transmission systems is preventing unintended downward movement or “backdriving” when the drive is not actively engaged. Products from a Helical Racks Factory typically exhibit a higher degree of self-locking due to the angular tooth engagement, which can help resist gravitational force to some extent. However, for safety and functional reasons, additional mechanisms such as brakes, counterweights, or non-reversible gear drives may be required to hold vertical loads securely in place. While the helical rack can contribute to load retention, complete reliance on tooth geometry alone is not advisable in critical applications involving heavy vertical loads.

Precision and Smooth Motion in Vertical Use

Another advantage of helical racks in vertical applications is their ability to provide smooth and controlled movement, especially during acceleration and deceleration phases. This is particularly valuable in equipment such as elevators, lifting systems, or vertical CNC axes, where abrupt movements can damage machinery or compromise accuracy. The gradual tooth meshing of helical racks ensures impact, causing less wear and increased service life. A Helical Racks Factory that produces high-precision components will offer products that are finely machined and capable of maintaining consistent performance regardless of orientation.

Design Adaptability and System Integration

One of the reasons why engineers turn to a Helical Racks Factory for vertical systems is the adaptability of the products. Helical racks can be custom-designed to match the load, stroke length, and installation constraints of a vertical setup. Whether integrated into a gantry crane, automated warehouse system, or vertical packaging machine, the versatility of helical racks supports a broad range of motion control needs. Their quiet operation and ability to handle both high loads and speeds further enhance their appeal in modern vertical motion designs.

Conclusion

In conclusion, products from a Helical Racks Factory are not only suitable for horizontal motion but also well-suited for vertical transmission when designed with the correct considerations. Their structural benefits — including better load distribution, reduced backlash, and smoother operation — support reliable and efficient vertical movement. While additional design elements may be needed to fully address load retention and safety in vertical configurations, the fundamental properties of helical racks make them a viable and often advantageous choice.