Jun 20, 2025

Understanding the Dynamics of High-Speed Transmission

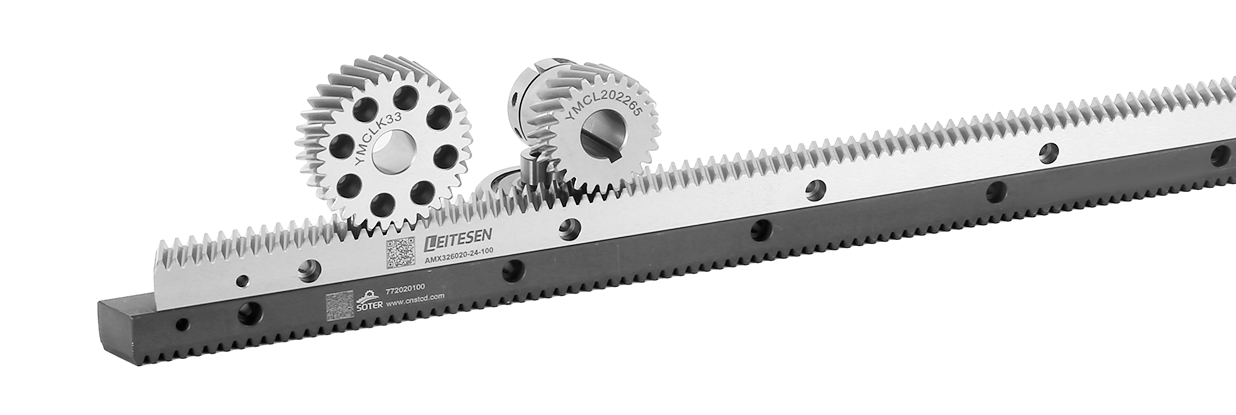

High-speed transmission systems demand components that deliver reliable performance, minimal vibration, and low noise. When considering whether a Straight Gear Rack is appropriate for such systems, it is essential to evaluate its mechanical characteristics, tooth engagement behavior, and compatibility with fast-moving gears. The performance of the gear rack at elevated speeds depends not only on the rack itself but also on the design of the entire motion system.

Tooth Engagement and Vibration Factors

A Straight Gear Rack features teeth that engage perpendicularly with the pinion gear. This straight-line engagement tends to cause instantaneous tooth contact, which can cause increased noise and vibration, especially as speed increases. At lower or moderate speeds, this is generally manageable. However, at higher speeds, the sudden impact during each tooth engagement may introduce undesired shock loads, resulting in wear or mechanical instability if not properly mitigated.

Material and Machining Precision Matter

Whether or not a Straight Gear Rack can function well in a high-speed environment also depends heavily on the quality of its material and manufacturing accuracy. Racks made from high-grade steel with tight machining tolerances and proper surface treatments (such as hardening or grinding) perform better at high speeds by reducing friction and improving tooth alignment. A well-machined rack with minimal runout and precise tooth geometry helps maintain smoother gear engagement, even as rotational speeds increase.

Lubrication and Maintenance Requirements

Efficient lubrication becomes critical when using a Straight Gear Rack in high-speed applications. Inadequate lubrication can cause heat buildup, increased wear, and tooth damage, particularly during continuous operation. Therefore, systems designed for high-speed motion must incorporate proper lubrication channels or automatic lubrication systems to keep the rack and pinion interface running smoothly. Regular inspection and timely maintenance also help prevent performance degradation over time.

System Design Considerations

While a Straight Gear Rack can technically be used in high-speed setups, designers must carefully consider factors such as load balancing, backlash control, and support structure rigidity. Without sufficient damping or structural reinforcement, vibrations at high speeds can amplify and affect positional accuracy or component longevity. Additionally, using smaller modules with tighter engagement tolerances may help improve performance but could limit load capacity.

Comparison with Helical Gear Racks

In many high-speed applications, helical gear racks are preferred due to their angled teeth, which allow for gradual engagement and quieter, smoother motion. Unlike straight racks, which may generate abrupt force transfer, helical racks distribute load over multiple teeth during meshing. This reduces impact and noise, making them more suitable for systems where quiet operation and precision at speed are priorities. However, they also introduce axial forces that must be accounted for in the design.

Use Cases for Straight Gear Racks at High Speed

Despite their limitations, Straight Gear Racks can still be effectively used in certain high-speed scenarios, particularly where the linear travel path is short, load is moderate, and cost-efficiency is important. Examples include pick-and-place devices, automated inspection arms, and lightweight conveyor systems. When high-speed motion is required alongside simple mechanical construction, a straight rack may offer a practical solution if properly optimized.

Conclusion: Conditional Suitability for High-Speed Systems

A Straight Gear Rack can be used in high-speed transmission systems, but its effectiveness is conditional. With proper material selection, precise machining, adequate lubrication, and careful system design, it can achieve stable and efficient performance. However, for extremely fast or precision-critical systems, alternatives such as helical racks may offer good results. Ultimately, the decision should be guided by specific performance requirements, operating conditions, and long-term maintenance considerations.