Jun 13, 2025

Tooth Geometry and Engagement Characteristics

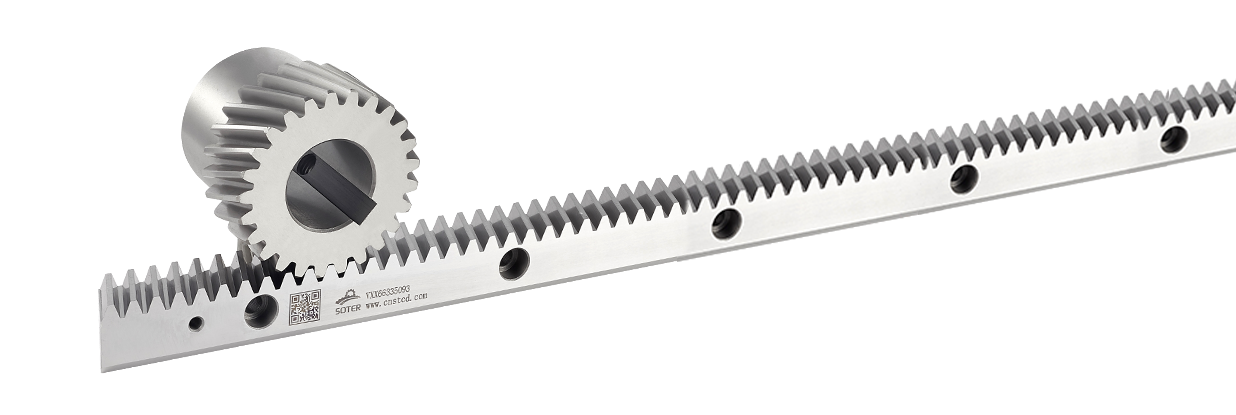

One of the noticeable differences between a Straight Gear Rack and a helical gear rack lies in the shape and orientation of their teeth. A straight rack has teeth that are perpendicular to the rack’s length, resulting in direct engagement with the mating gear. In contrast, a helical rack has angled teeth, which engage gradually and provide smoother meshing. This key distinction affects how each type performs in terms of efficiency, noise, and vibration.

Advantages of Straight Gear Rack in Simplicity and Precision

A significant advantage of the Straight Gear Rack is its simple design and ease of manufacturing. This simplicity allows for cost-effective production, straightforward installation, and easy alignment. In applications where precision and fast linear movement are important, such as CNC machines or basic automation systems, a straight rack provides reliable, direct motion with complexity. Additionally, straight racks tend to have less axial thrust, which means fewer side forces are applied to the gear shaft, simplifying system design.

Lower Cost and Easier Maintenance

Straight Gear Racks typically cost less than their helical counterparts, making them an ideal choice for budget-conscious projects or systems where high load capacity is not a top priority. Maintenance is also easier due to the less complex tooth design and alignment process. The straightforward structure makes inspection, replacement, and lubrication more manageable, particularly in modular or field-repairable mechanical systems.

Helical Rack Benefits in Smoothness and Load Capacity

Helical gear racks, due to their angled tooth design, offer smoother and quieter operation. The gradual engagement of teeth reduces impact and vibration during meshing, which is advantageous in high-speed or noise-sensitive applications. This smooth transmission is especially beneficial for robotics, printing machinery, and precision positioning systems where noise reduction and movement stability are critical. Moreover, the angled teeth allow for a larger contact area, increasing the gear's ability to handle higher loads compared to a straight rack of the same size.

Axial Load Considerations

One drawback of helical racks is the generation of axial thrust during operation. Because the teeth are angled, they apply a sideways force to the gear shaft as it rotates. This requires the use of thrust bearings or additional support structures, potentially increasing design complexity and cost. Straight Gear Racks do not generate this axial force, which simplifies bearing selection and mechanical layout, especially in space-constrained environments.

Wear, Efficiency, and Backlash

While helical racks generally produce less backlash and wear more evenly due to their smooth engagement, they may also introduce more friction, reducing mechanical efficiency slightly. Straight racks, while potentially noisier, tend to have higher transmission efficiency due to the direct path of force transfer. However, they may wear more rapidly under high-speed conditions if not properly lubricated or aligned.

Application-Specific Preferences

In high-speed, high-precision applications where noise and smooth motion are crucial, helical racks are often the preferred choice despite the higher cost and axial force management requirements. On the other hand, for systems that prioritize cost-efficiency, ease of maintenance, or simple motion control, Straight Gear Racks remain a practical and effective solution.

Conclusion: Selecting the Right Rack for Performance and Budget Needs

Both Straight Gear racks and helical gear racks offer distinct benefits depending on the application. While straight racks excel in simplicity, cost-effectiveness, and ease of alignment, helical racks are preferred for their smooth operation, quietness, and better load distribution. Choosing between them requires a clear understanding of the mechanical demands, speed requirements, and precision expectations of the intended system.