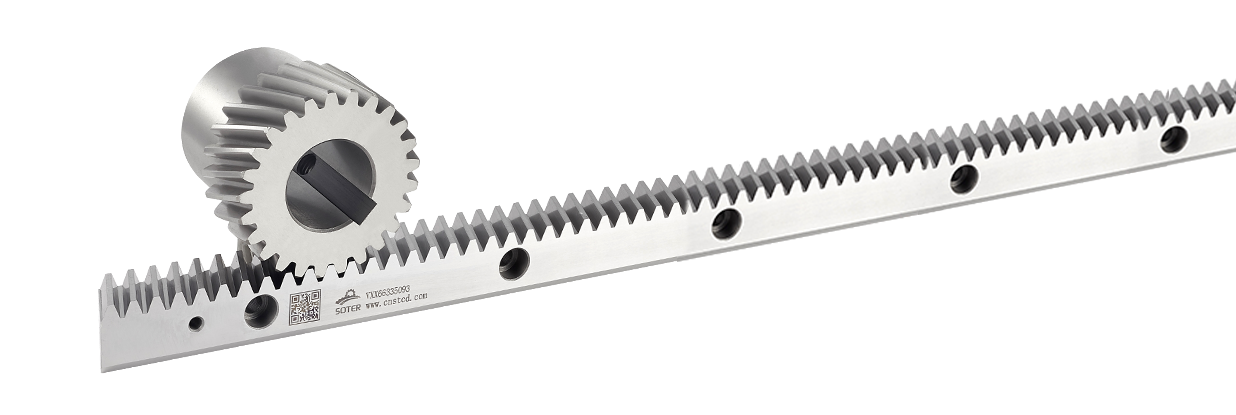

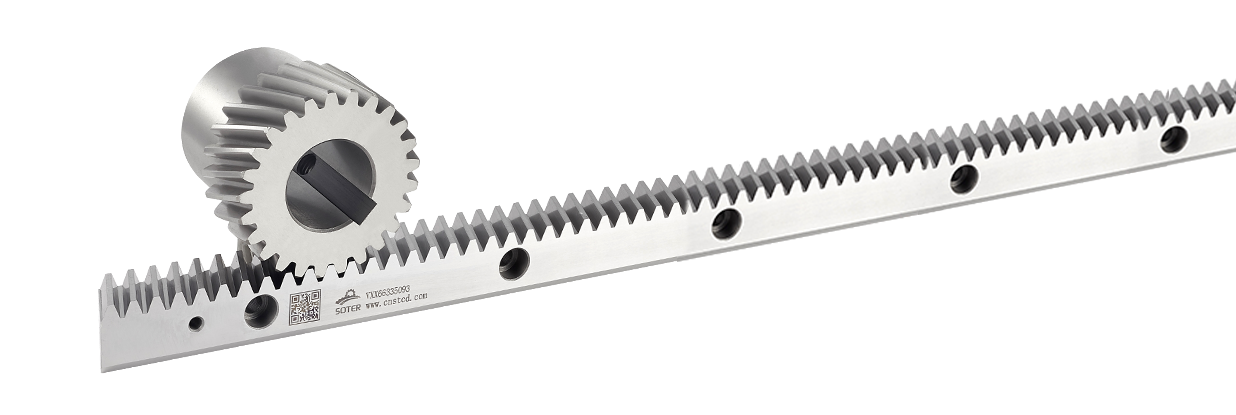

Helical gear racks are widely used in industrial machinery, automation systems, and precision equipment due to their smooth operation and high load-carrying capacity. However, the performance of a helical gear rack can be significantly influenced by temperature and environmental conditions. Helical Gear Rack Factory suppliers emphasize the importance of considering these factors during selection and maintenance. This article explores how temperature, humidity, and other environmental conditions affect the performance and longevity of helical gear racks.

Impact of Temperature on Helical Gear Rack Performance

- Thermal expansion and contraction: High temperatures cause the gear rack's metal to expand, potentially affecting meshing with pinions and causing dimensional inaccuracies. Conversely, extremely low temperatures can make the metal contract, increasing backlash and reducing precision.

- Material properties: Elevated temperatures can reduce the hardness and tensile strength of metals, while extremely low temperatures can make them brittle. Both conditions affect load-bearing capacity and durability.

- Lubrication effects: Temperature fluctuations influence the viscosity of lubricants. High heat can thin lubricants, reducing protection and increasing wear, while cold temperatures can thicken lubricants, causing higher friction and energy consumption.

Environmental Factors Affecting Performance

- Humidity and moisture: Exposure to high humidity or water can cause corrosion, particularly if the gear rack is not made from stainless steel or properly coated. Corrosion causes surface pitting, increased friction, and premature failure.

- Dust and debris: Industrial environments with dust, metal shavings, or sand can infiltrate the gear teeth, increasing wear and potentially jamming the rack and pinion system.

- Chemical exposure: Gear racks in chemical plants or outdoor environments may face acids, alkalis, or other corrosive agents that degrade materials or coatings.

- UV exposure: For outdoor applications, prolonged sunlight can affect painted or coated surfaces, reducing corrosion resistance over time.

Design Considerations to Mitigate Environmental Impact

Material selection:

- Alloy steels and stainless steels offer better resistance to temperature variations and corrosion.

- Surface treatments, such as nitriding or coating, enhance hardness and environmental resistance.

Lubrication strategy:

- Use high-temperature or low-temperature lubricants based on operational conditions.

- Consider sealed systems or protective covers to prevent lubricant degradation and contamination.

Protective housing: Enclosures, covers, or bellows shields can protect the gear rack from dust, moisture, and debris.

Precision tolerances: Accounting for thermal expansion during design ensures consistent performance under varying temperatures.

Operational Practices to Maintain Performance

- Regular inspection: Monitor for signs of wear, corrosion, or backlash, especially in bad environments.

- Proper lubrication schedule: Adjust lubrication frequency and type according to environmental conditions to maintain smooth operation.

- Temperature monitoring: For systems operating under high loads, monitor ambient and operating temperatures to prevent overheating.

- Alignment checks: Ensure the rack and pinion remain properly aligned, particularly after thermal cycling or exposure to environmental stressors.

Benefits of Considering Environmental Effects Early

- Extended service life: Selecting the right materials and protection strategies reduces premature failure.

- Consistent performance: Proper design and maintenance reduce backlash, wear, and efficiency loss caused by temperature and environmental factors.

- Reduced downtime: Preventive measures decrease the likelihood of unexpected breakdowns in critical systems.

- Lower maintenance costs: Using corrosion-resistant materials and appropriate lubricants reduces repair and replacement expenses.

Temperature and environmental conditions play a critical role in the performance and longevity of helical gear racks. High or low temperatures, humidity, dust, chemicals, and UV exposure can all impact material properties, lubrication efficiency, and overall system reliability. By carefully selecting materials, coatings, and lubrication strategies, and by implementing protective measures, engineers can ensure suitable performance. Working with experienced Helical Gear Rack Factory suppliers helps in choosing the right rack for specific environmental conditions, causing longer service life, consistent operation, and reduced maintenance costs.